We, at Ionitech, receive different tools and parts for nitriding from different Industries. And some of them pose challenges and requirements that stand out. We got a very interesting requirement - nitriding small gears made of steel grade AISI 4142 (42CrMo4), with a request to achieve a very small diffusion layer of less than 100 microns depth. This case stands out, and it is interesting because this steel grade is usually very good for nitriding and achieves a great balance of surface hardness and diffusion depth, as we will look into it in another of our studies. Still, the requirement was for a small diffusion depth of less than 100 microns.

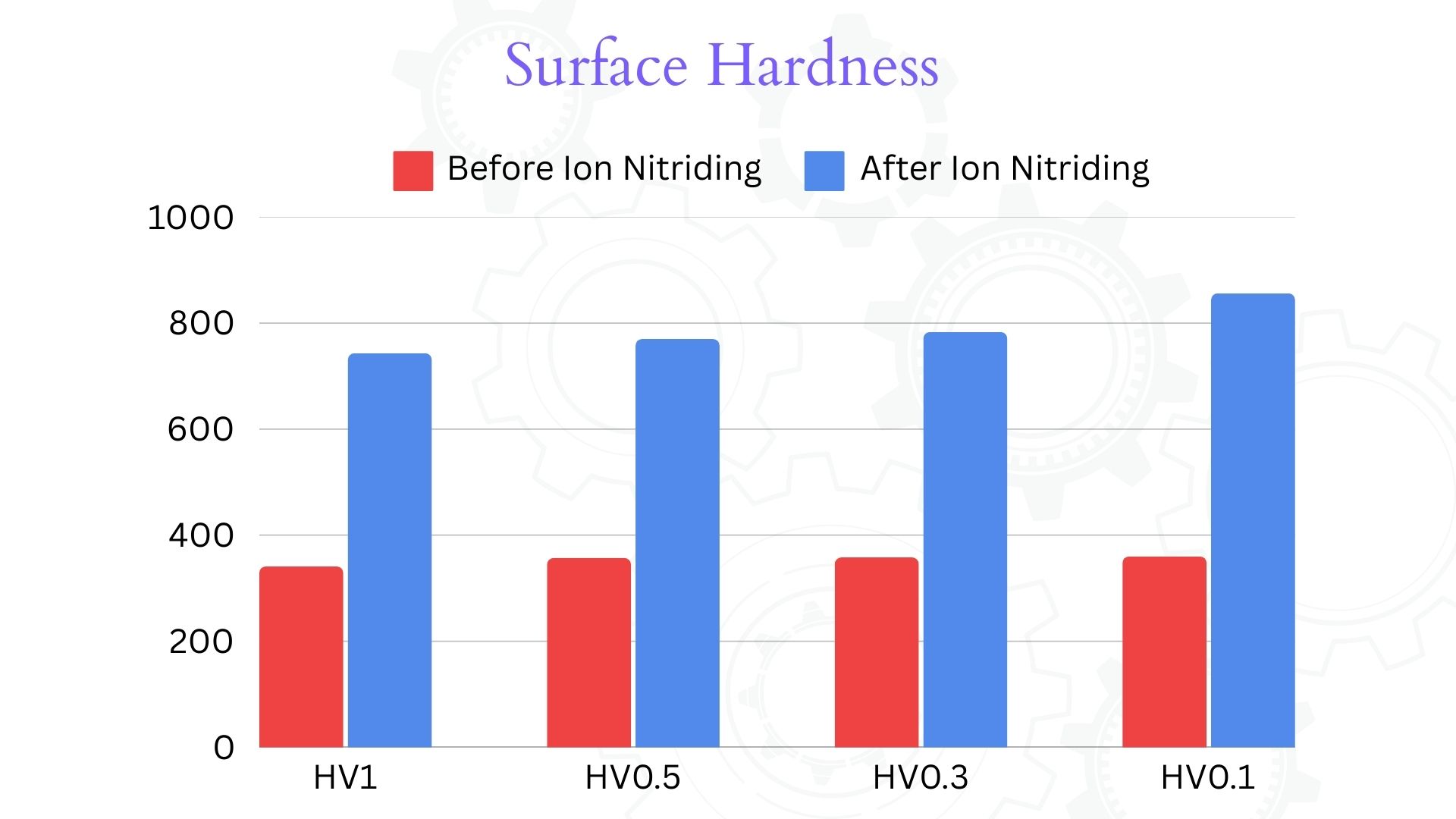

First, we start by measuring the surface hardness before nitriding. Measurement is done using a Vickers hardness tester, and we use the loads of 1 kg, 500 grams, 300 grams, and 100 grams. We measure a few times with each different load, and then we take the average for each and plot it on a graph.

Now, let us look at the two main challenges that we need to consider. The first one is achieving the requirement of a diffusion layer of below 100 microns and the second challenge is to have a uniform diffusion layer on top of the tooth as well as between the gear teeth. This is a challenge because of the very small size of the gears that need to be nitrided.

We carefully arrange the parts into the furnace, and we start the process. Ion/plasma nitriding requires careful arrangement of the parts in the chamber, so that the parts have a bit of distance between them and also the surfaces that require nitriding are visible, so that we achieve a good layer.

After the process, we measure the surface hardness again. The surface hardness with a higher load is a bit lower compared to the measurement with lower loads. This is because measuring with a higher load penetrates deeper into the layer and is reaching a place with less diffused nitrogen atoms, while the smallest load of 100 g will most probably show us the most accurate surface hardness because it will penetrate less of the surface and will have a higher percentage of diffused nitrogen. In most cases, it will even penetrate only in the achieved white layer.

Measuring the surface hardness with Vickers is a non-destructive method, but in order to measure the in-depth nitriding, we need to: cut the sample; put the cross-section into a mold; and polish it.

There are two main ways to determine diffusion depth after measuring. Total case depth, and Effective case depth. But for this study we will be looking at the Total case depth.

Total case depth is measured at 50 HV on top of the core hardness. So, first, we need to determine the core hardness.

We make a few measurements at the core, which is done roughly at center of the cross-section. We are lowering the load to 50 g because we want to be more precise in the measurement in depth. Again, we make a few measurements, and we get the average, which in this case is about 375 HV.

Now, we are going to measure the hardness in depth, starting from the top of the tooth and going down towards the core.

We are going to do the same in-depth measurements between the teeth.

A few measurements are done for each place in order to confirm the results are uniform. By doing this, we are going to get a graph of the hardness in depth. Going further away from the surface we will be measuring in places with less diffused nitrogen which means less hardness until we reach the core hardness. And this way we can determine up to where the nitrogen diffusion layer ends. We, also, take the same measurements in between the teeth and stack the two graphs together to see that a uniformity has been achieved. Diffusion depth is the same on top of the teeth as between them.

Finally, we will look into the metallography of the sample. We will etch it in a solution of nitric acid and then view it under a microscope with different magnifications.

As a conclusion we can say that ion nitriding of steel grade AISI 4142 is very suitable, achieving great surface hardness and a good diffusion depth, even when it is required to be smaller than what is normal for this steel. Most importantly, even though the gears were very small, excellent uniformity of the diffusion layer has been achieved as on top of the teeth as between them, and it is not a problem for Ion nitriding.

English (United Kingdom)

English (United Kingdom)  Русский (Россия)

Русский (Россия)  Български (България)

Български (България)  Español (España)

Español (España)