Ionitech’s Cold-Wall Ion/Plasma Nitriding and Ferritic Nitrocarburising Equipment

The heating of the parts, in a Cold-Wall plasma nitriding furnace, is carried out only by pulsed plasma created in the vacuum chamber. This type of plasma nitriding equipment is especially suitable for nitriding similar in shape and size batches of parts. The main advantages of this type of equipment are:

- Lower cost of the equipment

- Easy maintenance

- Lower consumption of electrical energy

The Cold-Wall vacuum chambers’ type could be:

- Door-type chambers

- Bell-type chambers

- Pit-type chambers

- Combined chambers loaded from the bottom and from the top

The vacuum chambers have double walls, with cooling water circulating in between. In order to decrease the heat exchange between the treated parts and the chamber walls, two stainless steel shields, separated by thermo-insulating wadding, are installed on the inside surface of the walls and the bottom.

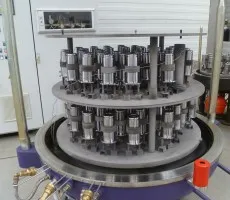

The parts are loaded on metal plates. These plates lie on support insulators, and are connected to the cathode of the plasma generator. The process of plasma nitriding could be viewed through a sight glass. The temperature during the process is measured directly in the parts using one or two thermocouples K-type.

The plasma generator has a specially developed safety mechanism to protect the tools and parts.

The gas vacuum system evacuates the chamber and fills them with treatment gases.

The process is carried out either with a mixture of hydrogen and nitrogen or with ammonia gas. Propane or natural gas are used for nitrocarburising. After the end of the treatment, the chambers can be filled with argon for accelerated cooling.

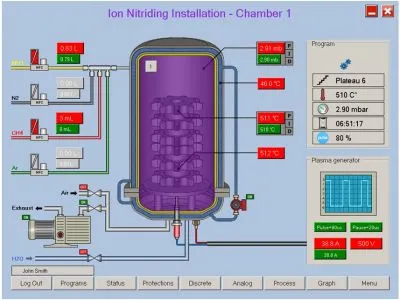

PC Control Panel - Absolutely User-Friendly and Full Control of the Process

The control system consists of a PC controller, main system controller and subsystems (transmitters and drivers) that are connected in a communication network. The Panel PC is equipped with a 15” touchscreen display and uses Windows operating system.

The technological process is completely automatic. All the main parameters are controlled by the system controller:

• Pressure in the working chamber

• Temperature of the processed parts

• Heat rate

• Ratio and consumption of working gases

• Process time length

• Pulsed Plasma Current

• Frequency of pulses

• Duty-cycle of pulses

• Temperature of cooling water

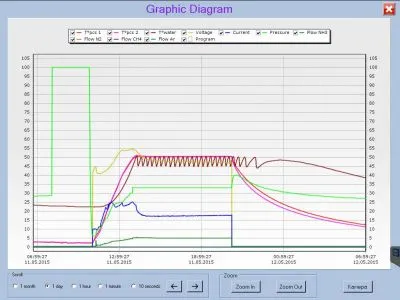

Our specifically designed application, IonView, implements the operator interface of the ion nitriding installation. It has the following capabilities:

• Visualization of the technological process parameters

• Review and editing of technological programs, even while the installation is working

• Archive of the technological processes

• Remote access to the archive

• Visualization of the alarms

• Alarm notification through e-mail and SMS-message

• Possibility to send process data to Ionitech as attached zip-file through email.

Ionitech Ltd. offers the following Cold-Wall plasma nitriding models:

Installation, model | Working volume, mm, Ø x h | Vacuum chamber type | Max. weight of loaded parts, kg |

ION-20CWI | 500 х 600 | Door-type | 200 |

ION-25CWI | 500 х 600 | Door-type | 300 |

ION-40CWI | 750 х 750 | Bell-type | 600 |

ION-50CWI | 750 х 900 750 х 1200 | Bell-type Bell-type | 1000 1000 |

ION-75CWI | 750 х 1800 1000 х 1000 | Pit-type/Combined Bell-type | 1500 1500 |

ION-100CWI | 750 х 3000 1000 х 1500 1000 х 2000 1300 х 1300 | Pit-type Bell-type Bell-type Bell-type | 2000 2500 2500 2500 |

ION-150CWI | 750 х 5000 1300 х 1800 1600 х 1600 | Pit-type Bell-type Bell-type | 2500 3000 3000 |

ION-200CWI | 1000 х 5000 2000 х 1000 | Pit-type Bell-type | 3500 4000 |

ION-300CWI | 2500 х 1500 | Bell-type | 5000 |

• Input voltage: 3x400V( 480V ) +10%/-15%, 50Hz ( 60 Hz )

• All installation models could be equipped with two chambers working separately - learn more about Ionitech's Double-Chamber System for no loss in technological time

• Working gases: ammonia, nitrogen, hydrogen, propane, methane

• Cooling gases: nitrogen, argon

• Working pressure: 1 - 8 mbar

• Time for manufacturing, 5 - 8 months (depending on the model).

If you have any further questions about our Hot-Wall equipment, please, don't hesitate to write to us: office@ionitech.com

English (United Kingdom)

English (United Kingdom)  Русский (Россия)

Русский (Россия)  Български (България)

Български (България)  Español (España)

Español (España)