Parts in the Pumping Industry:

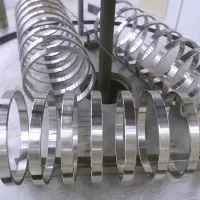

- Plungers

- Pistons

- Valves

- Gears

- Screws

- Impellers

- Rotors

- Shafts

- Bushings and Sleeves

- Case Rings

Requirements for the parts:

- For high Hardness

- For high Wear resistance

- For high Fatigue strength

- For Plastic deformation resistance

- For Lower friction

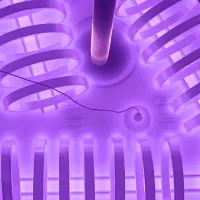

Ion Nitriding Solutions:

Significantly increasing the surface hardness, wear resistance and fatigue life of the parts, improving their lifespan and performance.

- Reducing the friction coefficient.

- Increasing the corrosion resistance.

- Post-Oxidation can be done after nitriding in the same process for further increase in corrosion resistance.

Improving these parameters will save from downtime and maintenance costs.

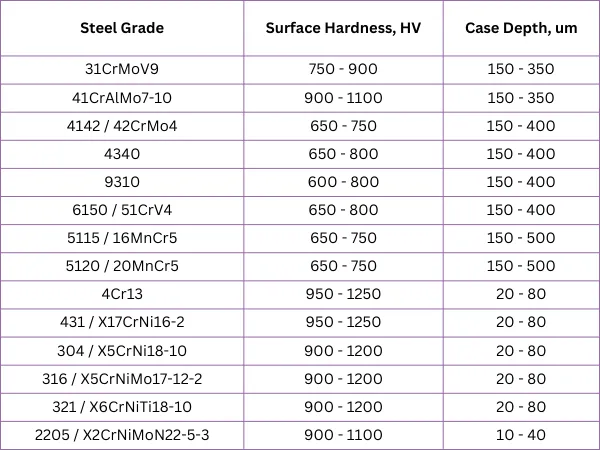

Steel Grades Used:

Hardness and depth values are recommended for the industry and exact values will depend on the nitriding process parameters.

This is not a full list of used steel grades

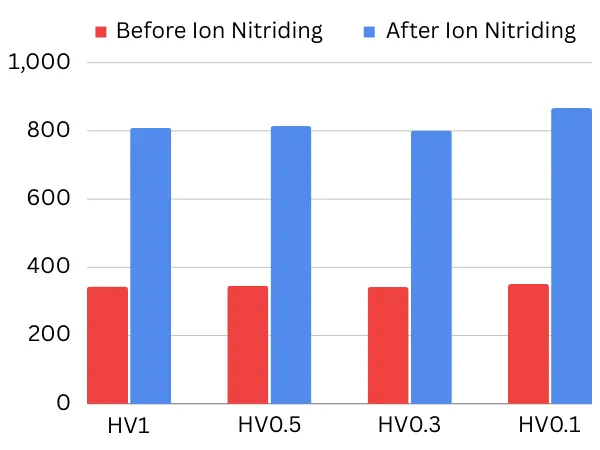

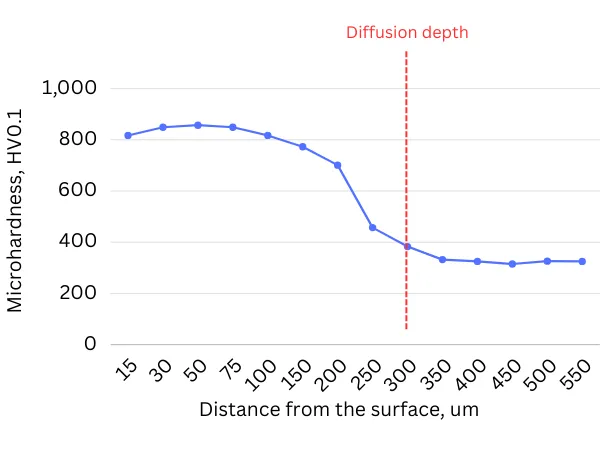

Example of 31CrMoV9 steel after Ion Nitriding - surface hardness and diffusion depth

English (United Kingdom)

English (United Kingdom)  Русский (Россия)

Русский (Россия)  Български (България)

Български (България)  Español (España)

Español (España)