Parts in the Plastic Injection Molding Industry:

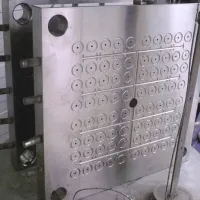

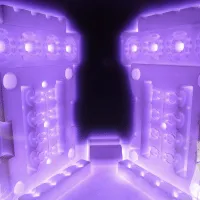

- Plastic Injection Moulds

- Screws

- Barrels

- Nozzle tips and nozzle bodies

- Side-action cores and cavity inserts

- Ejector Pins and sleeves

- Slides and lifters

- Bushings and guide pillars

Requirements for the parts:

- For high Wear resistance

- For high Fatigue strength

- For Reduced friction and adhesion

- For Corrosion resistance

Ion Nitriding Solutions:

Significantly increasing the surface hardness, wear (abrasive and adhesive) resistance and fatigue life of the tools, improving their lifespan and performance.

- Reducing the friction coefficient and the adhesion of the plastic material to the tools. Nitriding will also lower the friction for bushings and guide pillars.

- Increasing the corrosion resistance which is needed for certain additives and processing conditions.

Improving these parameters will save from downtime and maintenance costs.

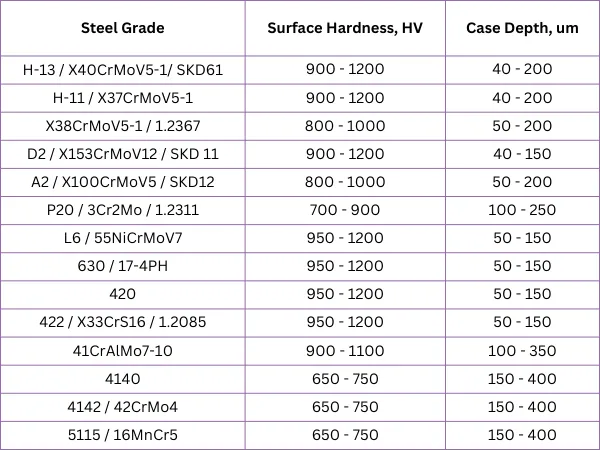

Steel Grades Used:

Hardness and depth values are recommended for the industry and exact values will depend on the nitriding process parameters.

This is not a full list of used steel grades

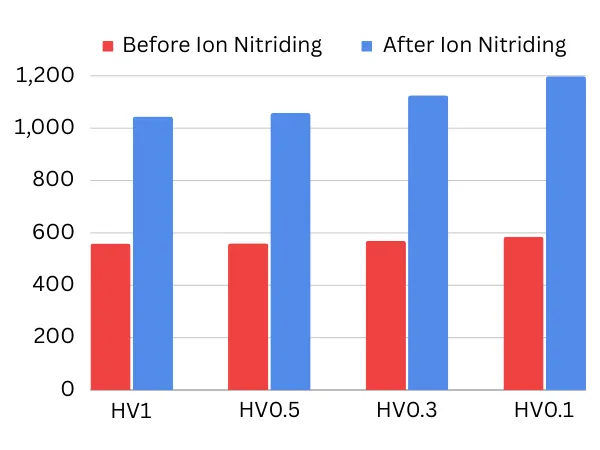

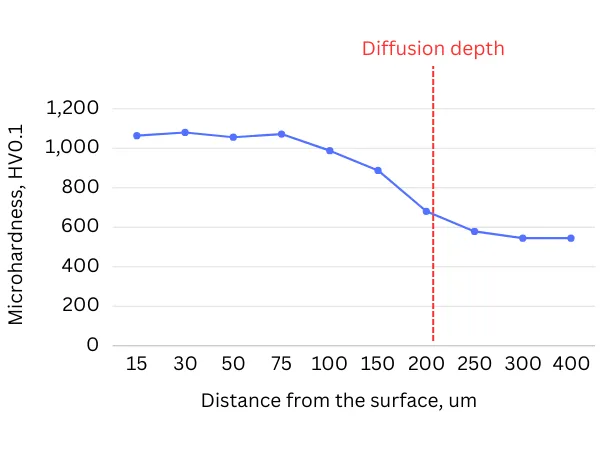

Example of H13 tool steel after Ion Nitriding - surface hardness and diffusion depth

English (United Kingdom)

English (United Kingdom)  Русский (Россия)

Русский (Россия)  Български (България)

Български (България)  Español (España)

Español (España)