Parts in the Thread Rolling Industry:

- Thread Rolling Cylindrical Dies

- Thread Rolling Flat Dies

Transmission parts in mechanisms of the presses – see Transmissions and Drive Systems Industry

Requirements for the parts:

- For high Hardness

- For high Wear resistance

- For high Fatigue strength

- For Plastic deformation resistance

- For Lower friction

Ion Nitriding Solutions:

Significantly increasing the surface hardness, wear (abrasive and adhesive) resistance and fatigue life of the tools, improving their lifespan and performance.

Improving the thermal fatigue resistance of the tools.

Reducing the friction coefficient.

Increasing the corrosion resistance.

Improving these parameters will save from downtime and maintenance costs.

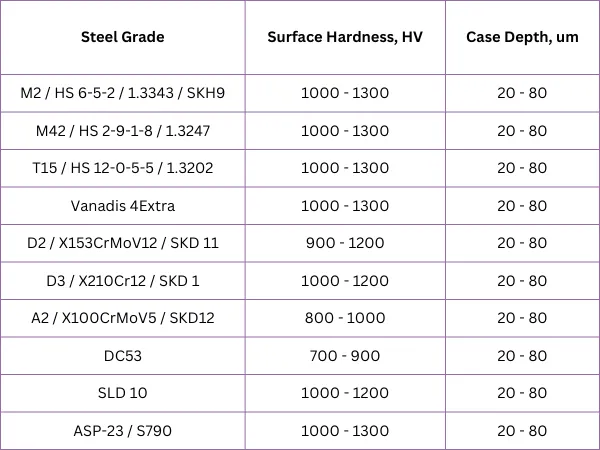

Steel Grades Used:

Hardness and depth values are recommended for the industry and exact values will depend on the nitriding process parameters.

This is not a full list of used steel grades

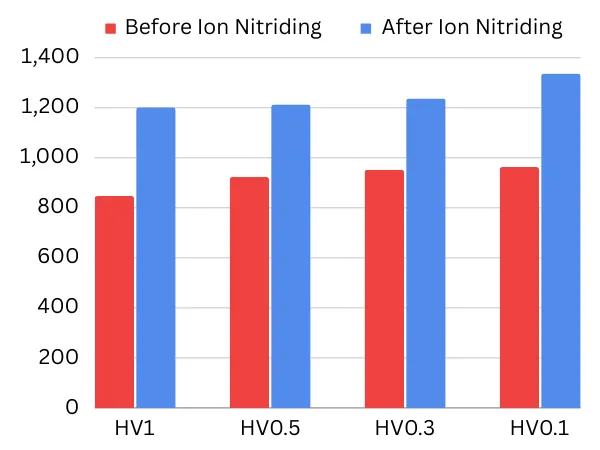

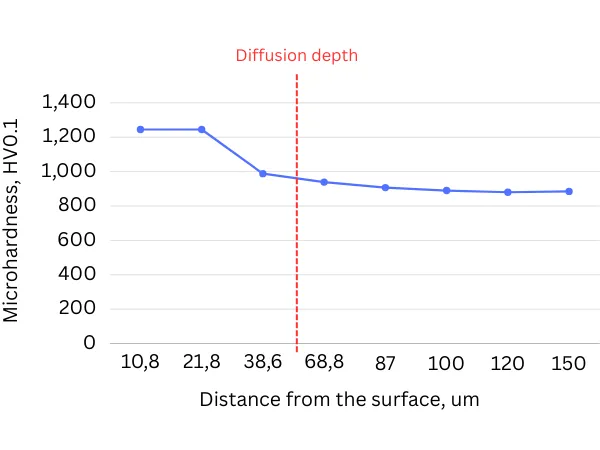

Example of Vanadis4Extra tool steel after Ion Nitriding - surface hardness and diffusion depth

English (United Kingdom)

English (United Kingdom)  Русский (Россия)

Русский (Россия)  Български (България)

Български (България)  Español (España)

Español (España)